Along general lines, transforming high-density plastic material through injection processes is much more effective than in any other type of process, as can be seen with rotomoulding, for example. This is because a series of high-precision events occur during the manufacturing process, all of which serve to make the end result a lot more aesthetically, functional and long-lasting, as well as ensuring that the end product complies with all the recyclability guarantees.

The transformation cycle consists of four synchronised phases that, as a whole, give rise to a quality product. This is because on the one hand, in its solid form, through injection, it is neither porous nor undulating and it is aesthetically pleasing and, on the other hand it is environmentally sustainable, in view of the energy efficiency involved in this type of process.

An effective process with distinct phases

The injection system makes it possible to produce cyclically. At the first phase, the high-density plastic granules are inserted into the feed hopper and towards the injection unit. From this point on, the plastic (chippings) distribution process begins through the spindle throughout the heating chamber. The spindle drags the plastic forward rapidly and it is melted in the chamber. The entire operation is activated by a hydraulic feeding system.

The melted polymer passes through a nozzle and enters the closure unit. This filling process must be carried out under high pressure, at exactly the right temperature and velocity. The injection system cooling process starts here. We would be prepared to say that it is the most important part of the process, because this is where the mould is housed, so the precision of all the elements plays a major role in the final outcome.

The mould is composed of two parts, a mobile plate and a fixed one. This unit contains the inserted material that will give shape to the end product, as well as the feeding channels, the conditioning system and the extractors. The piece remains there until it has cooled down. The process ends with the opening of the mould and the expulsion of the piece.

The injection processes make it possible to obtain highly complex pieces quickly and efficiently, and to do so from high-density, strong and durable polyethylene that is 100% recyclable without any further processes. The utilisation of a variety of materials also makes it possible to apply the processes to different sectors. In this sense, different types of plastics can be injected. Furthermore, when compared to other types of process, a much larger number of pieces per time unit can be obtained.

Benefits of the injection process

As we have already stated, this system has several benefits, including the following:

- High production level. Large amount of pieces manufactured unit of time

- Handling the material is reduced to a minimum

- The system can be used for both large and small pieces

- There is very little post-production waste

- The end product is consistent

- The end product is obtained in one single stage

- Potential for changing the design: colour control, mould control, etc.

- Hardly any or no finishing touches are required to the end product

- It is easy to reproduce the manufacturing conditions

- The cost of production is reduced because the process is automated

- The end product has very high quality and is 100% recyclable once it has reached the end of its working life

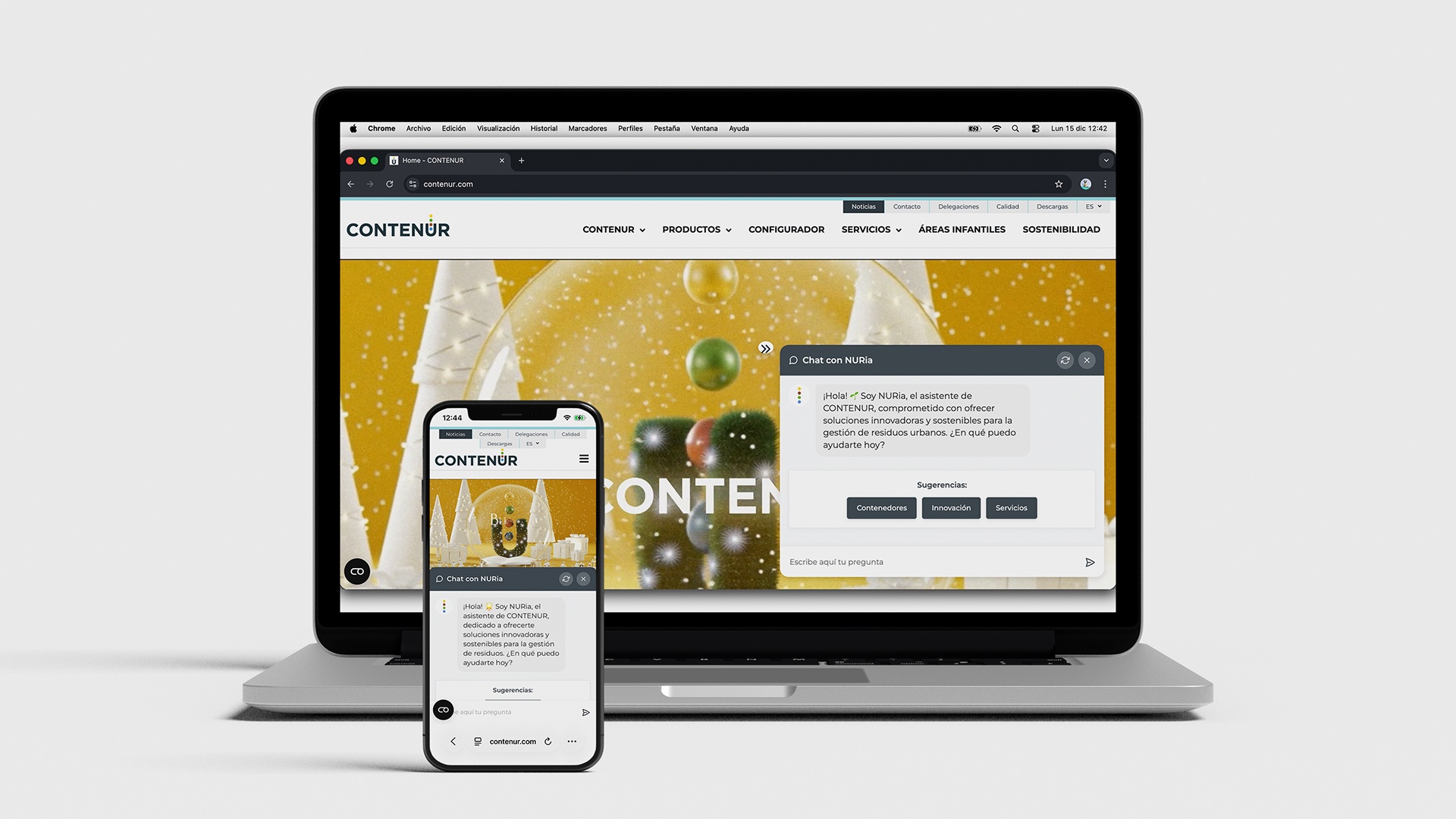

At CONTENUR we manufacture all our own containers using injection systems, obtaining a top-quality and totally sustainable end product.

If you wish to know more about how we implement this process when manufacturing our products

Please contact us